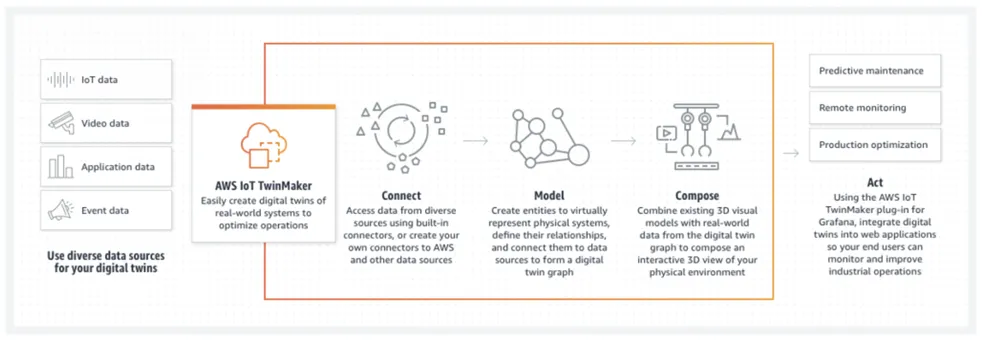

AWS IoT TwinMaker is a service that makes it easier for developers to create digital twins of real-world systems such as buildings, factories, production lines, and equipment. Customers are increasingly adopting digital twins to make better operational and strategic decisions in intelligent buildings, manufacturing, construction, energy, power & utilities, etc.

With AWS IoT TwinMaker, you now have the tools you need to build digital twins to help you monitor and improve your industrial operations. Digital twins are virtual representations of physical systems such as buildings, factories, production lines, and equipment that are regularly updated with real-world data to mimic the structure, state, and behavior of the systems they represent.

Before AWS TwinMaker, challenges that were impacting the device efficiency were as below:

Real-time monitoring for energy and power generated KPIs through different devices like Inverters, Generators, etc., in manufacturing plants.

Quickly pinpoint the device failures and perform maintenance activities to reduce the breakdown hours.

Remotely diagnose equipment issues with immediate access to all relevant operational data to enable faster decision-making.

Predicting potential downtime by identifying anomalies in sensors data and performing maintenance activities.

With AWS TwinMaker, we can quickly set up a 3D virtual design of the physical plant and enhance monitoring of all the devices without creating a separate web application.

Note - AWS IoT TwinMaker is generally available in regions of US East (N. Virginia), US West (Oregon), Asia Pacific (Singapore), Asia Pacific (Sydney), Europe (Frankfurt), and Europe (Ireland), with more regions to come soon.

Referenced website - https://aws.amazon.com/iot-twinmaker/